Introduction

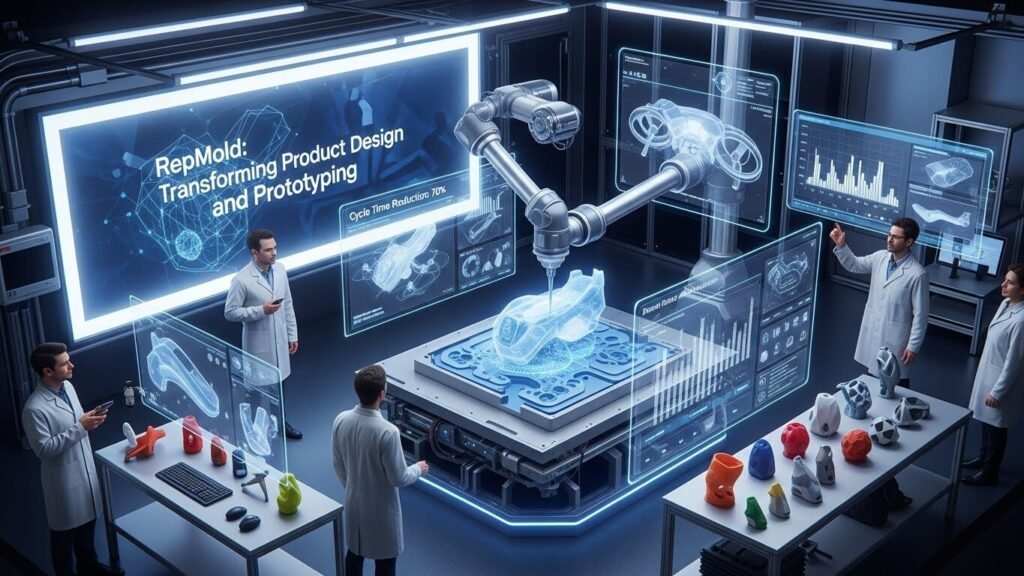

In today’s fast-paced manufacturing world companies is constantly looking , looking for faster smarter and more , more cost-effective ways , ways to turn their ideas into real products. And yes that’s where Raybold comes in and that’s where it comes in. You know what? Whether you’re a startup building your own prototype or an established company improving an existing design Repmold plays a critical role in modern manufacturing. Guess what? Unlike traditional manufacturing methods that require heavy tooling and long lead times Remold focuses on speed flexibility and precision.

And oh yeah A product group fails not because of a bad idea but because of neglected testing and development. Repold helps solve this problem by enabling manufacturers to create precise molds , molds for short-run production and prototyping. guess? Seriously This means real testing with real materials before committing to mass production. With the development of industries such as automotive medical consumer electronics and industrial equipment Rebold has become a trusted and reliable solution to reduce risk save money and improve , improve products and quality from the beginning.

Table of Contents

Guess what? What is repmold?

do you know Repold is a patented manufacturing technology used to create prototypes and small , small production molds with high precision. These molds are designed to replicate final manufacturing conditions allowing manufacturers to test parts under real-world conditions.

How Repmold Works

Remold typically combines advanced CNC machining, high-quality materials, and precision engineering. Instead of investing in expensive steel molds upfront, manufacturers use remold to:

- Validate part design

- Test material behavior

- Check assembly fit and function

- Gather real performance data

This approach is especially useful when product designs are still evolving.

Why Repmold Matters in Modern Manufacturing

Traditional tooling can take months and cost a fortune. Repold changes this equation by offering a smarter alternative.

Key Benefits of Repmold

- Faster mold development compared to traditional tooling

- Lower upfront costs

- Ability to make design changes easily

- Real-material testing instead of assumptions

For example, a consumer electronics company designing a new device casing can use remold to test durability, heat resistance, and assembly accuracy before committing to mass production.

Repmold vs Traditional Molding

Understanding the difference helps companies choose the right solution.

Like, Advantages of Repold over traditional molds

Speed: Repold molds can be produced in weeks instead of months

Flexibility: Design changes are easier and cheaper

Reducing risks: Problems are recognized early

Cost control: No need for expensive and long-lasting tools

Traditional molds are still ideal for mass production, but jumping right in without testing often leads to costly , costly mistakes.

Industries That Use Repmold

Repmld is not limited to one industry. Its adaptability makes it valuable across multiple sectors.

Common Industries Using Repmld

- Automotive (interior parts, brackets, connectors)

- Medical devices (housings, surgical components)

- Consumer products (enclosures, accessories)

- Industrial equipment (functional components)

In the medical industry, for instance, repold allows manufacturers to test devices under strict compliance standards before final approval.

Common Problems Repmold Helps Solve

Many product development challenges can be traced back to poor testing and rushed decisions.

Problems Without Repmold

- Design flaws discovered too late

- High tooling costs with no flexibility

- Poor fit between assembled parts

- Material performance issues

Repmod acts as a safety net. By producing realistic molds early, companies can detect weak points and improve designs before scaling.

Real-World Example of Repmold Use

Imagine a startup developing a new power tool handle. The design looks perfect on screen, but once produced, users complain about grip comfort and balance. Instead of redesigning after mass production, repmld could have been used to create test molds, allowing real users to provide feedback before launch. This simple step can save thousands in rework and brand damage.

Why Repmold Is a Smart Business Decision

Repmld is not just a technical choice—it’s a strategic one. Businesses that use repold often launch better products, faster, and with fewer surprises. It supports innovation without forcing companies to gamble large budgets on untested ideas.

By bridging the gap between design and full-scale manufacturing, repold helps turn concepts into reliable products with confidence.

Materials Commonly Used in Repmold

One major reason repmld delivers reliable results is the careful selection of materials. Unlike rough prototypes, remold uses materials that closely match final production behavior.

Popular Repmold Materials

Manufacturers choose materials based on performance needs, cost, and testing goals:

- Aluminum alloys for fast machining and durability

- Engineering plastics for functional testing

- Steel inserts for areas exposed to high pressure

- Silicone or urethane for flexible part evaluation

For example, aluminum molds are widely used in repmod because they provide excellent thermal conductivity and can withstand repeated injection cycles during testing.

Design Best Practices for Repmold Success

Repmld is powerful, but poor design choices can still lead to failure. Smart planning makes all the difference.

Key Design Guidelines

- Keep wall thickness consistent to avoid warping

- Design proper draft angles for easy part release

- Avoid unnecessary complexity in early stages

- Focus on functional testing, not cosmetic perfection

A common mistake is overengineering a repold tool as if it were a final production mold. Remold works best when used as a learning tool, not a final solution.

Cost Considerations and Budget Control

One of the strongest selling points of repmod is cost efficiency—but only when used correctly.

How Repold Saves Money

Repmld reduces expenses by:

- Eliminating large upfront tooling investments

- Shortening development cycles

- Reducing redesign costs later

- Minimizing material waste

For small businesses and startups, this can be the difference between launching a product and abandoning it due to budget limits.

However, repold is not “cheap manufacturing.” It is smart manufacturing. Companies that treat it as a shortcut often misuse it and lose its real value.

Limitations of Repmold You Should Know

No manufacturing method is perfect, and repmld is no exception. Understanding its limits helps set realistic expectations.

Where Repmod May Not Fit

- Not ideal for very high-volume production

- Limited mold lifespan compared to hardened steel tools

- Slight surface finish differences may appear

- Not suitable for extreme pressure cycles long-term

Repold is best used as a bridge—not a replacement—for full-scale manufacturing.

Repmold vs Rapid Prototyping

Many people confuse repold with 3D printing or basic prototyping, but the difference is significant.

Key Differences

- Rapid prototypes focus on shape

- Repold focuses on function and performance

- Repmld uses production-like materials

- Results are closer to real manufacturing conditions

For example, a 3D-printed part may look correct but fail under stress. A repolded part reveals those failures early—when fixes are still affordable

How Repmold Improves Product Quality

Quality problems often surface after a product reaches customers. Repold shifts quality control to the earliest stage.

Quality Improvements Through Repmold

- Better dimensional accuracy

- Real assembly testing

- Improved material performance validation

- Early detection of stress points

This proactive approach builds stronger, more reliable products that perform well in the real world—not just in design software.

Future of Repmold in Manufacturing

As product , product lifecycles shorten and customization increases reconfiguration has become more important than ever. Manufacturers need flexible solutions that support rapid innovation without high risks.

The emerging trends are:

Integration with digital simulation tools

CNC methods and hybrid tools are faster

Improved material options

Increased acceptance of start-ups and SMEs

Repmld is evolving from a niche solution to a mainstream manufacturing strategy.

Conclusion

Repmold , Remold is more than a manufacturing technology but an effective decision-making tool. You know , know what? By allowing manufacturers to test designs materials and functionality before , before large-scale production reconfiguration reduces risk and increases confidence. It saves time controls costs and improves product quality in a way that cannot be achieved by traditional methods alone.

When , When used correctly Repold , Repold bridges the gap between concept and reality. And oh yeah It helps companies avoid costly mistakes and bring better products to market faster. Like , Like In a competitive manufacturing environment reconfiguration is not only an option , option but also a strategic advantage.

Also Read This; Best Why Pyntekvister is the Next Big Trend in Handmade Decoration